INTEGRATED CIGARETTE PACKAGING LINE

Our journey began in machine building for the cigarette industry initially with Packet wrappers and gradually the complete downstream packing machines including Boxers, Overwrappers & Case packers. Progressively EMS created capability for design & development and extended the product portfolio to higher speed ranges of 300 ppm & 400 ppm cigarette downstream packing machines; whilst simultaneously venturing into other applications in the tobacco industry.

CIGARETTE PACKING LINE

200 – 225 ppm Cigarette Downstream Packing Machines

Hinge Lid Packer (Model: PAC 250)

Description

PAC 250 is a versatile cigarette packing machine designed for efficiency and flexibility in handling various types of tobacco products. The machine is capable of producing up to 200~225 packs per minute, ensuring a high level of productivity. It is suitable for a range of tobacco products, including (filter) cigarettes from King Size to Super Slims, cigarillos, filter rods. The machine offers multiple packing styles to cater to diverse market preferences, including square corner packs, beveled edge packs, round corner packs, Half round packs.

Features

- Speed range: 200 – 225 ppm

- Electrical & Automation

- Robust construction

- Tray inverter (4000 style trays)

- Fitted with a cigarette turret. This helps to eliminate cigarette miss-feed – therefore improving machine efficiency.

- Cigarette turning rollers to be driven by independent motor

- Missing cigarette ends detector

- Foil cutting unit –Unit complete with single carbide cutting knife and carbide serrating knife

- Double bobbin holder for Foil with Foil auto-splicing unit

- Sealer bed driven by indexing gearbox through heavy-duty timing belt complete with plastic sealer bed pockets

- Automatic Blank loading system

- Packet Drying Drum with Teflon lining for smooth handling of packs

- Auto ejection of faulty packs

- PLC and HMI (Touch screen) – The touch screen provides many user-friendly features such as production data, speed selection, fault displays with alarms and diagnostic tools

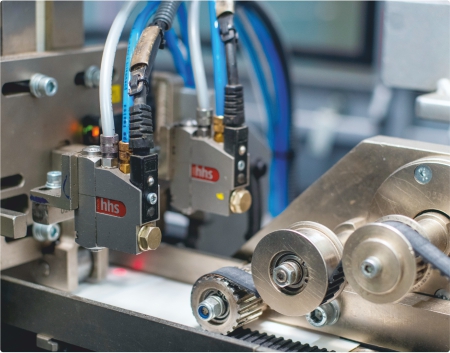

HHS Glue Nozzles

Auto Splicing of Foil

Auto Blank Feeding

Tax Stamper (Model: STP 225)

Description

STP 225 is a compact, stand-alone stamp application unit design for easy integration into any hinge lid packing combinations. Packets are delivered along an in-line input conveyor band and a star wheel/ plunger separates the pack and transfers it to the flights of the main packet conveyor which then delivers them positively towards the applicator roller where the stamp is applied. The glue is applied through gravure system and the glue pot is designed for easy access and maintenance.

Features

- Wide-range application to different packet dimensions.

- Automatic detecting and ejecting packets without a stamp.

- High operation efficiency and low wastage.

- Easy operation, and convenient maintenance.

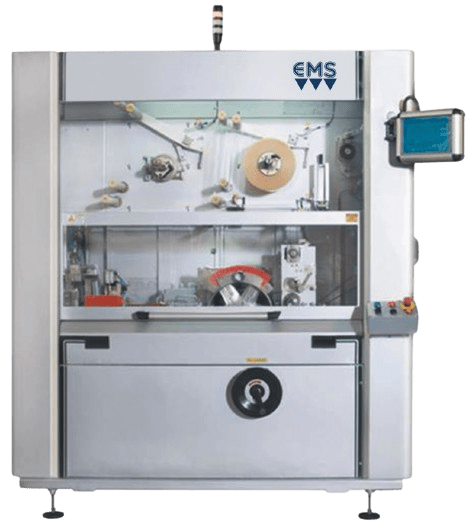

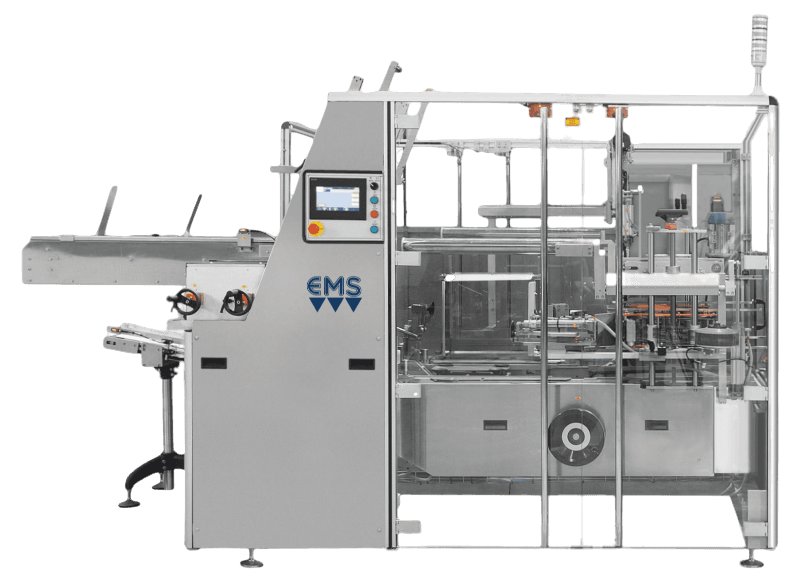

Packet Wrapper (Model: Wrapper 250)

Description

The packet wrapper machine (Model: Wrapper 250) is a proven work horse. The machine construction is very robust and it works on the principle of a turret mechanism which guarantees excellent wrapping quality even at higher speeds.

The cartons from the upstream machine are fed into the Wrapper through the infeed conveyor system and the cartons are then separated by a plunger before it enters the turrets along with the cut film of required length.

The turret slot grips the carton securely with the film and then the long seam folding and sealing operation is done. As the carton exits the turret, it passes through the side folds and sealing station where the clean envelope folds are formed and the sides are sealed. Multistage sealing feature with precise folder profiles ensures the wrapping quality.

Additionally, at the exit, ironing heaters are provided for both top & bottom faces of the carton to provide a tight finish and excellent aesthetics of the final pack.

Features

- Output speed: 250 ppm (speed depends on packet dimension)

- 6 station CAM Indexer for turret indexing

- SIEMENS PLC with HMI (Touch Screen panel)

- Auto Speed regulation depending on packet in-feed

- Static charge eliminator

- Precision cutter head with HHS knives

- Double Bobbin holder system with manual Splicing deck

- 2 stage moving top heaters & 4stage moving side heaters

- Auto heater retraction during machine stop

- Ergonomically positioned hand wheel for machine setting

- Safety clutch

- Machine guards with positive safety inter locks

- Sensors for monitoring packet, BOPP & TOR

- Ironing heater for enhanced pack finish

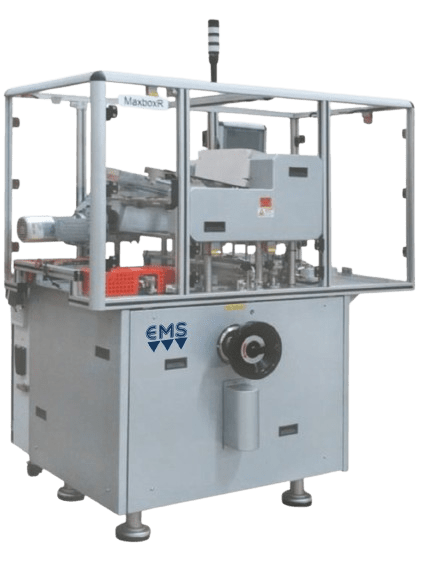

Boxer (Model: Max Boxer)

Description

The Boxer or Multi-box machine works on a wrap-around type concept. It has a robust construction with a main frame which houses all the Cam shafts and drive links that actuate the mechanisms of the machine. The machine is very compact & user-friendly.

The collated pack from the upstream Wrapping machine is received directly through a chute. The flat blanks are stored in a magazine. Pick-up arm with vacuum cups gently pick each carton at a time and then the carton is transferred to the required position through rollers.

The collated cartons are then transferred in to the blank and the flaps of the carton blank are glued with cold glue and then folded to form the box. Standard gluing system is through a glue pot with a finger applicator.

The glued box then passes through side heaters to seal the glued area of the box. The guides and folders are precisely mounted to provide accurate box formation and its squareness.

Features

- 25 outer per minute (speed depends on packet dimension, collation matrix, and outer size)

- PLC with Touch Screen HMI

- 4 stage Moving side heaters

- Temperature Control through PLC

- Auto heater retraction during machine stop

- Ergonomically positioned hand wheel for machine setting

- Safety clutch for main drive

- Machine guards with positive safety interlocks

- Sensors for material supervision & operator safety

- Includes one set of format parts

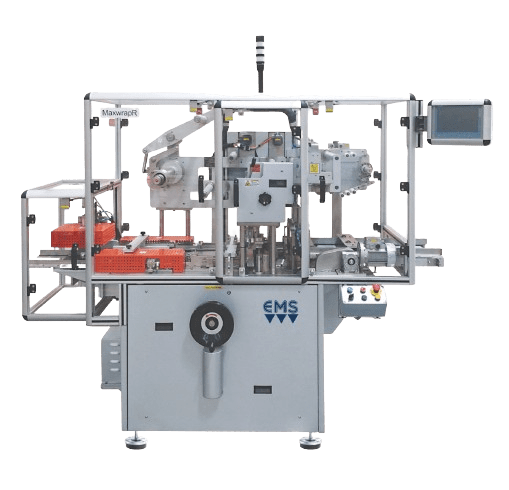

Overwrapper (Model: Max Wrap)

Description

The Max Wrap is a very compact and efficient machine that works on a linear principle. The film is unwinding through a servo motor to ensure the precise length of the film and consistency.

The film is cut by a positive system and the cut film is transferred by suction belts to maintain the position concerning the max wrap. The film subsequently wraps the multi-box and the long seam folding & heating takes place. The multi-box then moves through the side folding zone where the envelope folding and sealing are performed.

Built-in Ironing heater unit for both the top & bottom face of the multi-box is an added advantage in this machine to enhance the overall finish of the multi-box.

Features

- Output speed: 25 outer per minute (speed depends on outer size)

- Film pulling system (Servo)

- PLC with Touch Screen HMI

- 4 stage Moving side heaters

- Temperature Control through PLC

- TOR unit (Tear off tape)

- Auto heater retraction during machine stop

- Ergonomically positioned hand wheel for machine setting

- Safety clutch for main drive

- Machine guards with positive safety interlocks

- Sensors for material supervision & operator safety Includes

- Link-up conveyor to Boxer

Auto Case Packer (Model: CPS 500)

Description

Auto case packer is a versatile machine which is capable of handling a wide range of carton sizes and collation matrix.

Features

- Output speed: Upto 6 cases per minute (speed dependent on product size, collation matrix, and shipper size)

- Pusher driven by servo for quick adjustment of strokes and gentle handle of outers.

- Positive case opening and forming mechanism.

- Driven in-feed magazine for positive case transfer.

- Flexible to handle a wide range of case sizes.

- Easy & fool proof adjustments with scales for quick size changes.

- Large case magazine to hold up to 80 cases.

- Sensors for product monitoring and operator safety.

- PLC controlled with Touch screen HMI.

- Positive funnel/mouth piece to guide the collated cartons into the case.

SIGMA SERIES

400 ppm Cigarette Downstream Packing Machines

Tax Stamper (Model: CTX 300)

Description

CTX 300 is a compact, stand-alone stamp application unit design for easy integration into any hinge lid packing combinations.

CTX 300 is extremely flexible and accommodates a wide range of stamp sizes and positions. The advantage is that the machine can be adapted to suit various packet input orientations.

Packets are delivered along an in-line input conveyor band and a rotating star wheel diverts the packets into a down drop chute. The down drop can be straight or spiral – clockwise or anti-clockwise – depending on the packet orientation. At the foot of the down drop, the packets are delivered in front of the flights of the main packet conveyor which then delivers them positively towards the applicator roller where the stamp is applied.

Features

- Output speed: 300 ppm (speed depends on packet dimension, orientation, and stamp position)

- Flexible for pack infeed orientation

- Positive stamp pick and application system

- Stamp perforation

- HHS Nozzle gluing system (cold glue adhesive)

- Servo Indexed pack transfer

- Camera detection system for missing stamp.

- Auto rejection of packs with missing stamp

- PLC with Touch Screen HMI

Wrapper (Model: Sigma WR4)

Description

The Wrapper (Model: Sigma WR4) is a cutting-edge wrapping machine designed for precise and efficient packaging. Key features include a Servo film pulling and cutting system, Vacuum Belt Cutter head, 8-station turrets with globoidal CAM indexers, Suction turret, and 3-stage top heaters for consistent sealing.

The machine ensures quality packaging with Positive indexed pack delivery, 3-D folders, 5-stage side heaters, and an Ironing heater with an indexed belt. Safety features like a clutch and auto discharge enhance reliability. It incorporates advanced elements like motorized BOPP bobbin unwinding, static charge eliminator, auto splicing, motorized TOR unwinding, motion control, and Servo Drives.

User-friendly with a touch screen HMI, it boasts an auto-centralized lubrication system and a Rittal electrical cabinet for durability. The Sigma Wrapper offers versatility and precision in the packaging process.

Features

- Servo film pulling and cutting system

- Vacuum belt Cutter head system

- 8 station turrets with globoid CAM indexer (Bettinelli-Italy / Heinz – Germany)

- Suction turret feature

- 3 stage top heaters controlled by Servo for constant sealing time

- Positive indexed pack delivery system (packs are transported separately during folding & sealing operations to get the right control and quality)

- 3-D folders

- 5 Stage side heaters controlled by Servo for constant sealing time

- Ironing heater with separate top & bottom stations and indexed belt to transport packs separately and provide excellent finish of the pack

- Auto discharge facility in delivery zone during machine stop to empty packs

- Safety clutch to avoid damage to machine parts

- Auto centralised lubrication

- Motorized BOPP bobbin un-winding

- Static charge eliminator (SIMCO, USA)

- Auto splicing unit for bobbin change-over

- Motorized TOR unwinding (suitable for Jumbo TOR)

- Motion control

- Servo Drives

- Touch screen HMI with latest features

- Rittal electrical cabinet

Boxer (Model: Sigma BR4)

Description

The Boxer (Model: Sigma BR4) – a state-of-the-art solution for precision and efficiency in packaging. Boasting features like a positive blank pick-up system, a top heater designed for long seams, and a three-stage side heating mechanism, this machine excels in ensuring optimal carton formation.

Seamless operation and extended lifespan are achieved through the auto retraction of side heaters, a safety clutch, and advanced motion control.

The Boxer is equipped with servo drives and a cutting-edge touch screen HMI, ensuring accuracy and providing a user-friendly control experience. Backed by a Rittal electrical cabinet, this machine stands out as a premier choice for contemporary packaging requirements.

Features

- Pack collation unit to create the required matrix.

- Positive blank pick-off system.

- Top heater for long seam.

- 3-stage side heaters to ensure glue drying and proper carton formation.

- Auto retraction of side heaters during machine stop.

- Safety clutch to avoid damage to machine parts.

- Motion control

- Servo Drives

- Touch screen HMI with the latest features

- Rittal electrical cabinet.

Includes:

- Built-in collation system.

- One set of format parts.

Overwrapper (Model: Sigma OR4)

Description

Overwrapper (Model: Sigma OR4) is a high-tech packaging solution designed for efficiency. It features a 6-station turret with a parallel CAM indexer, 2-stage top heaters with auto-retraction, and a positive indexed carton delivery system for precise control.

The machine ensures quality sealing with 4-stage side heaters, auto-retraction during stops, and motorized film unwinding with splicing deck.

It incorporates a servo film pulling system, suction belts, and a motorized TOR unwinding system. Safety features include auto-reject of defective cartons, a safety clutch, and motion control.

The user-friendly design includes servo drives and a touch screen HMI with the latest features, all housed in a reliable Rittal electrical cabinet.

Features

- 6-station turret with parallel CAM indexer.

- 2-stage Top heaters for a long seam with auto retraction during machine stop.

- Positive indexed carton delivery system (cartons are transported separately during film folding & sealing operations to get the right control and quality).

- 4-stage side heaters to ensure good sealing quality and finish.

- Auto retraction of side heaters during machine stop.

- Auto-discharge of cartons in the delivery zone during machine stop.

- Motorized film unwinding system with splicing deck.

- Servo film pulling system and Servo cutting through the rotary knife.

- Suction belts to transport the cut film positively.

- Motorized TOR unwinding system (suitable for Jumbo TOR).

- Built-in Top & Bottom Ironing/Shrink heaters to provide a tight finish.

- Auto-reject of defective cartons including splicing detection.

- Safety clutch to avoid damage to machine parts.

- Motion Control.

- Servo drives.

- Touch Screen HMI with the latest features.

- Rittal electrical cabinet.

Includes:

- One set of format parts